Research and Impact

Research Vision and Strategy

Download our detailed Engineering Research Strategy December 2024 here.

The overall vision of research excellence in interdisciplinary themes will continue to act as the fundamental ethos in the Department.

- The 3 focus SDGs enable the Department to align our research activity with the key global challenges represented in both the UK Industrial Strategy and the UN Sustainable Development Goals agenda.

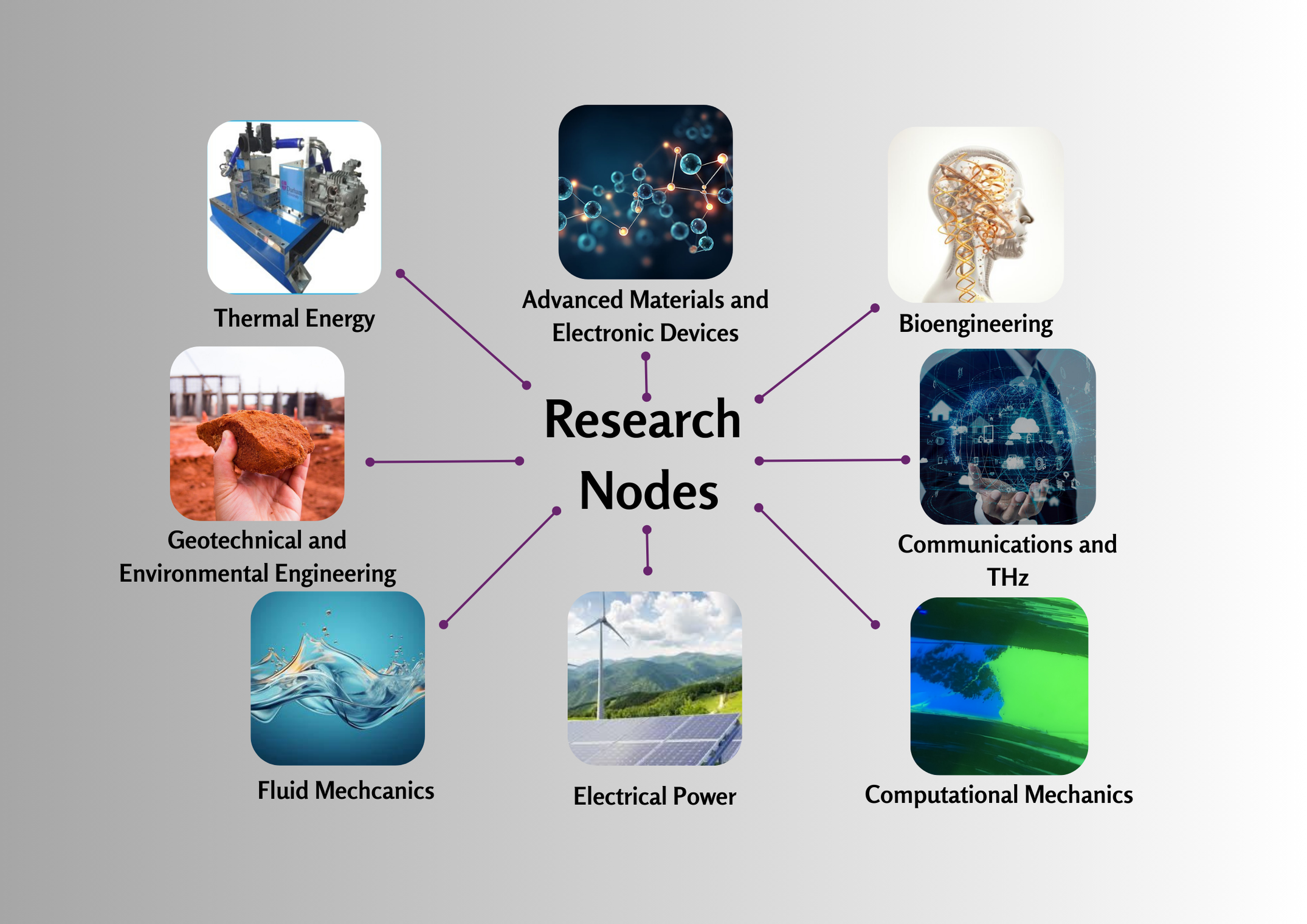

- The 8 Research Nodes cut across the SDGs and place staff in groups based on technical expertise and interests. They are how we organise ourselves day-to-day.

In addition, collaboration with colleagues across the wider university and the Research Institutes, is a key facilitator for our research, as well as collaboration with leading academic and industrialists in the UK and worldwide. The overall research strategy in the Department of Engineering includes a desire to diversify the research funding sources by increasing the industrial engagement with our research activity. The Department strategy aligns with the overall University strategy of Quality rather than Quantity, reflecting the world class research across the breadth of the institution.

Get in touch

Contact us to find out more about our department.

Department of Engineering

Durham University

Lower Mount Joy

South Road

Durham

DH1 3LE

Tel: +44 (0) 191 334 1700

/prod01/prodbucket01/media/durham-university/departments-/engineering/74202-5112X1676.jpg)