How physics is transforming our household cleaning products

Our strategic partnership with Procter and Gamble (P&G) has enabled interdisciplinary research projects across experimental, computational and theoretical physics.

These projects have led to new formulations and manufacturing processes for laundry detergents, the design of new liquid-repellent surfaces and improved testing of laundry and dishwasher products.

Creating the world’s smallest washing machine

Washing clothes at lower temperatures means clothing is less likely to shrink or fade. On average you can also save up to 57% on running costs by washing at 30°C when compared to washing at 40°C.

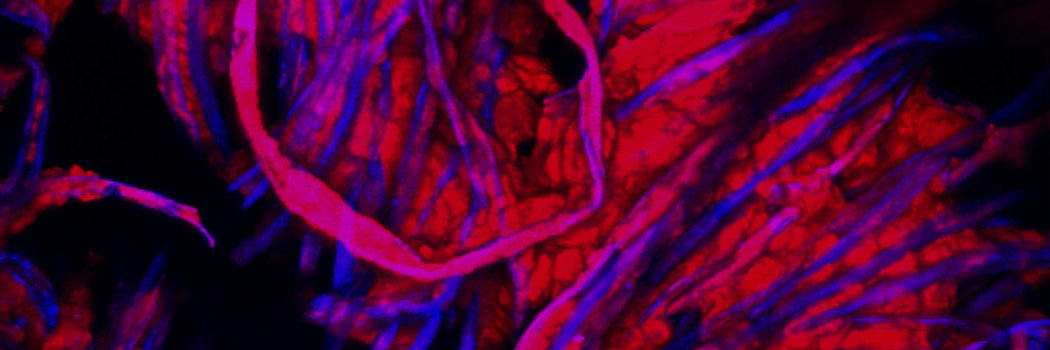

P&G wanted to improve grease removal in laundry at lower temperatures and with smaller amounts of water. This minimises environmental damage as well as energy costs, but the process is difficult to study in detail as grease is optically active – causing images to be blurred or distorted - making it difficult to judge the effectiveness of different detergent formulations.

Professor John Girkin is a world expert in adaptive optics and their applications to biological materials. Using 3D optical microscopy, combining widefield and beam scanning imaging, Professor Girkin was able to develop ‘the world’s smallest washing machine’ under a microscope.

This visualisation of grease removal with different lipase-based formulations was at a scale that had never been seen before, and identified a new physical process important in the washing cycle. Bubbles of CO2 which were released from the fat by the detergent helped remove the grease from the surface. The discovery of this CO2 release enabled P&G to modify their flagship laundry products, helping to ‘blow the fat’ from the surface of the material.

Computational studies of cleaning on structured surfaces

Understanding how liquids and semi-solids can be efficiently removed from solid surfaces is critical across many P&G product categories, from shampoos and detergents to paper towels.

A project to develop new liquid-repellent surfaces led by Dr Halim Kusumaatmaja and his team from the Centre for Material Physics has developed powerful computational approaches to study how liquids interact with solid surfaces. These simulations have helped P&G reduce costly experimental time and resources.

Dr Kusumaatmaja has also undertaken research with P&G’s Transformative Platform Technology division in Cincinnati to enable more efficient removal of soils, and to optimise the design parameters of superhydrophobic and liquid-infused surfaces.

Modelling of astronomical events used in the production of laundry powder

Spray drying is an important energy-intensive step in laundry powder production. P&G wanted to optimise the spray drying process used in producing their laundry powders.

Research led by Professor Richard Bower adapted AI techniques and algorithms first developed to model astronomical events, and applied them to optimise the operation of P&G’s blow-drying towers. Professor Bower was able to use these algorithms to provide real time optimisation of the control parameters from limited data.

Thanks to both the energy and cost savings P&G are now rolling out this tool across all their drying plants.

Find out more

- Centre for Advanced Instrumentation

- Centre for Materials Physics

- Institute for Computational Cosmology

Main image shows the world’s smallest washing machine as seen under a microscope.

/prod01/prodbucket01/media/durham-university/external-location-photography-/city-shots-/82922-1-1920X290.jpg)